With the advent of ever-cheaper three-dimensional (3d) printers, the cost of 3d printing has dropped by several orders of magnitude and the printers themselves have become much more available. Currently, there are several 3d printers with different properties available to members of the IUB campus. In addition, there are commercial services that can do the printing after you upload the proper file. This document describes how users of the EM Center have accessed different 3d printers, but it will start with some general information related to 3d printing.

Printing Three-Dimensional Models

Principles of Three-Dimensional Printing

The fundamental idea behind 3d printing is that successive two-dimensional (2d) layers of material are laid on top of one another and bonded together. This has lead to the use of the term additive manufacturing to describe 3d printing and to repackaging traditional machining as subtractive manufacturing (i.e., an object is created by removing the undesired material).

Since it is easy to visually slice any 3d object into a series of thin, 2d slices, the actions of a 3d printer are fairly easy to conceptualize: a 3d model is cut into slices (usually on the order of 100 μm, but some 3d printers use layers as thin as 16 μm) and the slices are manufactured (either cut out of a sheet or built up essentially as a series of drops or bits assembled into a 2d layer) and bonded together. The properties of the final product depend on things like the fineness of the layering, the physical and mechanical properties of the materials in the layers and the strength of the processes that hold the layers together.

Materials that can be used for 3d printing range from standard office paper to sugar (making edible 3d objects!) to rigid plastics such as ABS (acrylonitrile butadiene styrene) to flexible plastics to a variety of metals. The starting materials for 3d printing can range from paper, plastic or metallic sheets to a variety of liquids to metallic or plastic "wires" to granulated materials that are bonded together using chemicals, lasers, heat, or electron beams. Some 3d printers even use inkjet technology to spray binding material onto successive powder layers. For the most part, the cost of printing a 3d object is based on the volume of material in the final product and prices are usually reported in cost per cubic inch (or cm).

File Formats

Several file types can be used by 3d printers, but probably the most common format is called STL, which stands for either Stereo Lithography or Standard Tessellation file format. This format is supported by many CAD (computer aided design) systems and both Amira and UCSF Chimera can output scenes in STL format. The STL file describes the surface geometry of a 3d object as a set of polygons (mostly if not exclusively triangles) connected along their edges, and in the most simple case, the STL file contains neither scale information nor color coding. There are several ways to include color information in a STL file (whether you can do this depends on the software creating the STL file), but bear in mind that different 3d printers may or may not support printing with color.

| File Format | Colors | Textures |

|---|---|---|

| STL | No | No |

| VRML | Yes | Yes |

| SCAD | No | No |

| OBJ | Yes | Yes |

| DXF | No | No |

The more triangles that are used to describe an object, the larger the STL file becomes. In addition, the curved surfaces in a printed object become "smoother" as the number of triangles increases (i.e., an observer ceases seeing the curved surface as a set of connected flat, triangular surfaces). However, some 3d printers (and some commercial 3d printing companies) have limits on the size of files that can be printed, and you may find it necessary to adjust file sizes (e.g., the number of triangles, the fineness of sampling, however one wants to describe this) for a particular printer.

Different Types of Three-Dimensional Printers

There are lots of 3d printers (and examples are show in the images at the top of this page), but they fall into two major groups: commercial 3d printers with prices measured in the tens of thousands of dollars and desktop (or home use) 3d printers which can be as inexpensive as a few hundred dollars. Printers that use the various materials mentioned above can be found within these two groups, with corresponding differences in the price of raw materials. Probably the most important thing to keep in mind is that the technology is developing rapidly, and much of what is written here will undoubtedly be obsolete soon!

Examples of Three-Dimensional Printing from EMC Users

On-Campus Three-Dimensional Printers

The object shown in the image to the right (a model of BK virus, a human polyoma virus similar to SV40) was printed by David Morgan using a 3D printer located in the School of Fine Arts. The contact person for this printer is Nicole Jacquard, the printing medium is gypsum and this model is un-colored.

The starting 3D model was generated using cryoTEM images of BK virus and extensive computational analysis using the auto3dem package. The 3d model was then visualized using Chimera, and the STL file that was sent to Nicole was standard chimera output (~3 MB, small enough to e-mail to her). Nicole was able to adjust the size of the output so that this model is slightly larger than a baseball. The cost of the BK virus model in the image was less than $40. Anyone wanting to see this model should contact David Morgan at dagmorga@indiana.edu.

Commercial Three-Dimensional Printing Services

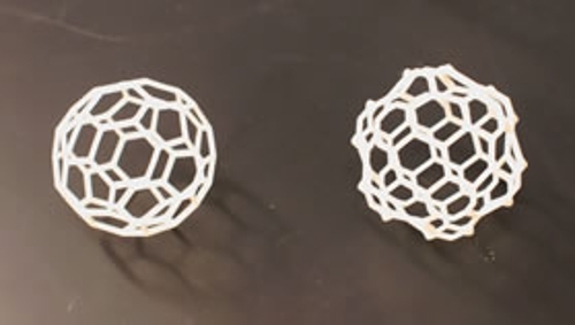

The objects shown in the images to the left and below were printed by Andrey Maluytin in Bogdan Dragnea's lab using a company called Shapeways. Although it is impossible to tell from the image, the shapes to the right were printed using shapeways' "Elasto Plastic" formulation (a proprietary plastic) and are highly deformable (but then return to their original form when the deforming pressure is removed). One of the shapes below was printed in the same Elasto plastic but the two others are in a harder plastic called "Strong and Flexible." Andrey created the STL files he uploaded to shapeways using UCSF Chimera (and also used Chimera to generate the 3d models for the wireframe shapes shown above).

The shapways 3d printing service lets a customer upload a file that is less than 64 MB or 106 triangles in size. Shapeways can use various 3d file formats (including non-STL formats that contain color). They currently offer 3d printing in over 30 materials (including plastics, ceramics, some metals, etc.) at what appear to be extremely reasonable prices. Costs for printing are based around a per cubic cm price for each of the different materials (ranging from $0.75 for gypsum to $20.00 for sterling silver), and will thus depend on the overall size of the object printed, the average thickness of all the parts, etc. The two objects shown in the image at the left are ~6 cm in diameter and cost $5.50 each, while the three virus structures at the right required more material, are ~5 cm in diameter and cost ~$30 each. Shapeways offers a 10% academic discount that Andrey did not know about when he ordered the two wireframe pieces. Anyone wanting to see these models should contact Bogdan Dragnea at dragnea@indiana.edu.